Home » Adjustable Scrapers

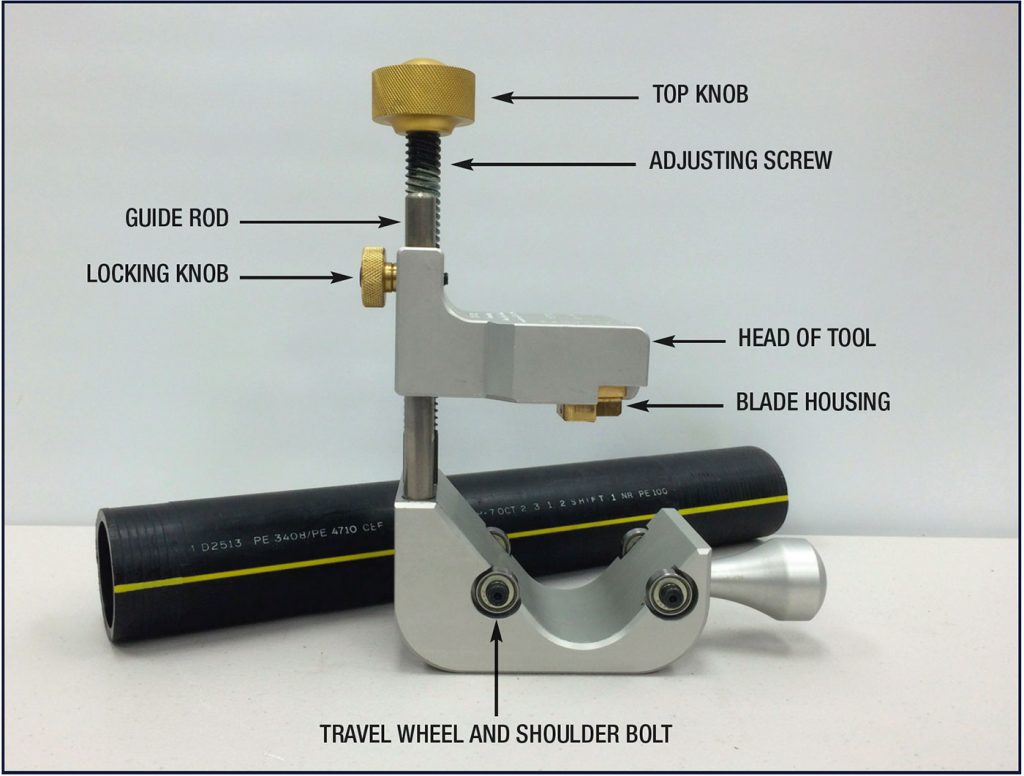

The Adjustable Scraper line of tools intended use is for the preparation of polyethylene pipe prior to performing an electrofusion.

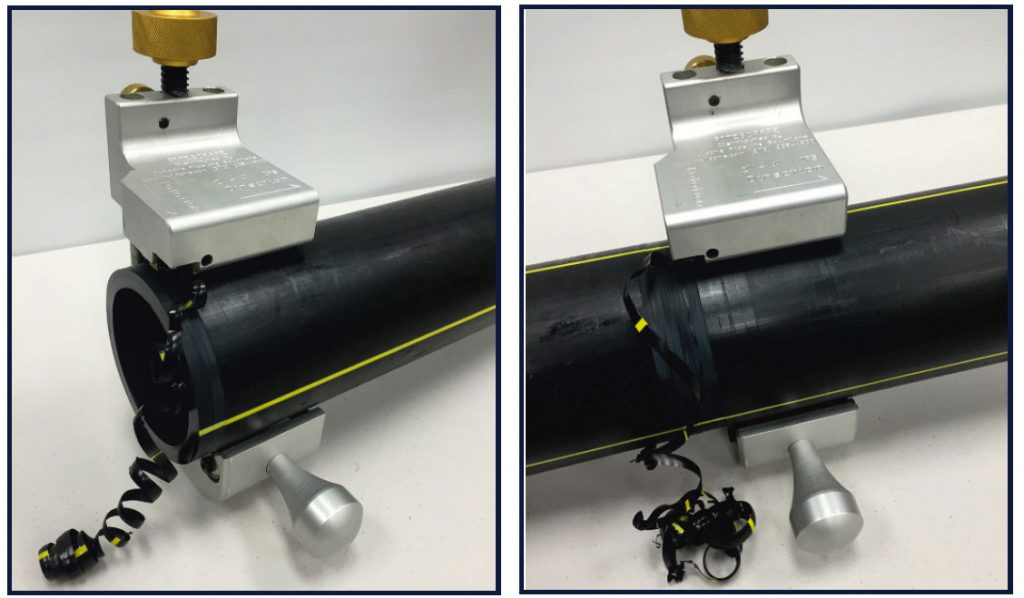

All Adjustable Scraper tools peel a “ribbon” of oxidized polyethylene material off of the pipe to expose the virgin material beneath the surface.This booklet will help you understand the safety, functionality, and maintenance for the Adjustable Scraper line of tools.

It is the responsibility of the end user to ensure the tool is functioning properly and that proper electrofusion protocols are followed.

Prior to using your Adjustable Scraper tool, verify the following parameters;

NOTE – If any of the aforementioned items fail, do not use the tool, take corrective action

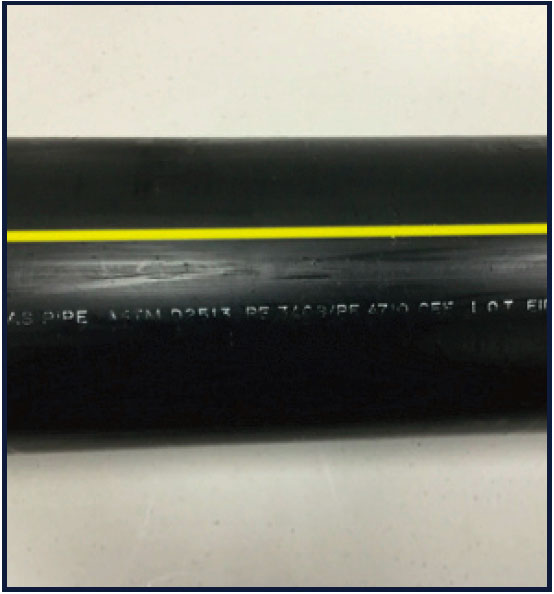

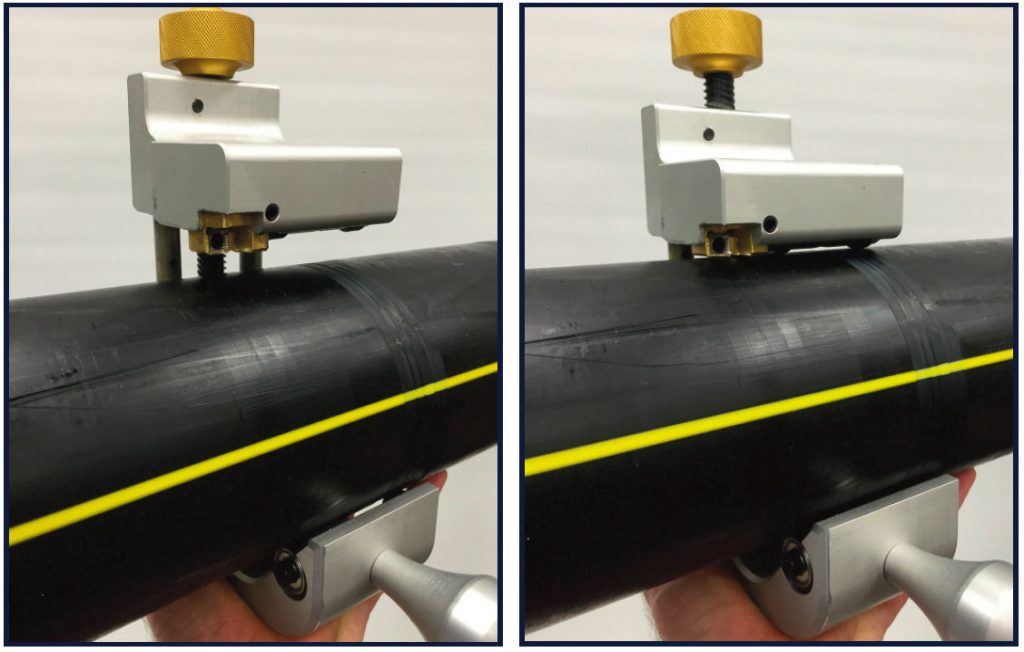

Prior to installing a Adjustable Scraper Tool make sure the pipe has been properly prepared.

Before you install your Adjustable Scraper, verify that your tool is appropriately sized for the pipe you are about to scrape.

Once the tool is installed properly, rotate the tool around the pipe following the directional arrows on the top of the tool.

Your Adjustable Scraper tool should be periodically checked for visible wear and tear. Although many of these items are covered in the operating instructions, the following list of items will assist in keeping your tools operating properly.

Our facility is technically sound and meets all the criteria you’d expect from a top-class machining location. Our innovative machines continue to produce cost-effective, accurate measurements and cuts, making turnaround a quick and easy process. And with a spacious warehouse we’re ready to handle high demand large projects, and are refined enough to make precise measurements for even the smallest of projects.